EE75-EE160 Two-Stage Horizon

Applications:

- Paper & pulp

- Machine tool shops

- Textiles

- Cement

- Automotive

- Steel making

- Food processing

- Oil carry over less than 2ppm

- Grouped service points ensure easy access to components for maintenance

- Optimized cooler design and cooling fans ensure low running temperatures

- Versatile neuron II micro controller provides easy diagnostics of system parameters

- Models available as bare units/side located drier/variable speed drive variants

- Wide range of accessories – vertical air receivers, driers, automated supply side controller and variable frequency drives to meet diverse operating conditions

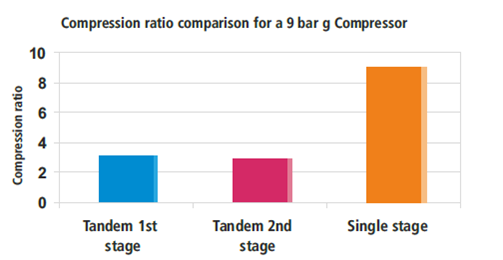

Ratio of Suction to Discharge of a Screw Airend: A single-stage compressor, operating at a discharge pressure of 9 bar, has a compression ratio of 1:9 (Ratio of Suction to Discharge of a Screw Airend) .In a two-stage compressor operating at the same discharge pressure, the compression ratio is divided between the two-stages of tandem airend and is about 1:3 in each stage. This makes the airend more reliable and efficient due to smaller loads on the bearings. The volumetric efficiency of two-stage is better than single-stage compression.

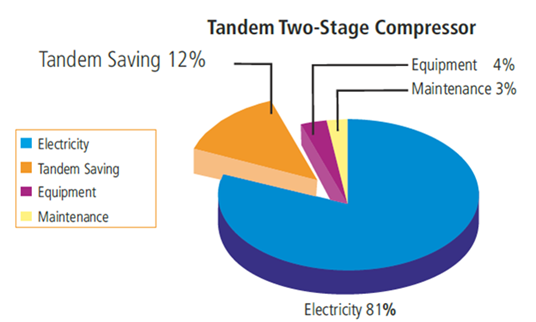

Energy Efficiency of Tandem Screw Compressors: ELGi offers tandem screw compressors to help industries reduce their operating and energy costs. It is two-stage compressor, having energy efficiency as the key features. The compression is done in two-stages to improve the volumetric efficiency and thereby contributing to decrease in power consumption and increase in saving energy costs. Tandem air compressors consume 8-12% less power and offer a return on investment within 8-15 months when compared to single-stage compressors.